Barium titanate ceramics has...

Barium titanate ceramics has a broad market space and high-end demand

Barium titanate ceramics are ceramic materials with barium titanate (BaTiO3) or its solid solution as the main crystalline phase. Barium titanate has the characteristics of high dielectric constant, low dielectric loss, high resistivity, high withstand voltage strength and excellent insulation. It is a strong dielectric compound material. Barium titanate ceramics made from it is one of the most widely used materials in electronic ceramics. Barium titanate ceramics can be widely used in the manufacturing of capacitors, thermal components, piezoelectric components and other components, and the market demand continues to grow.

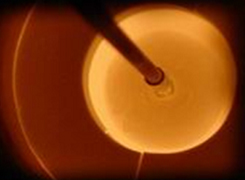

Barium titanate ceramics take barium carbonate and titanium dioxide as the main raw materials, first synthesize barium titanate under high temperature conditions, then add additives such as sintering aids and dopants, and finally make barium titanate ceramics through the processes of mixing, ball milling, drying, tablet pressing, sintering and slurry brushing. Sintering is an important link in the preparation of barium titanate ceramics, and its process directly affects the properties of barium titanate ceramics. The sintering processes of barium titanate ceramics mainly include millimeter wave sintering, microwave sintering, pressureless sintering, high pressure sintering and so on. Among them, millimeter wave sintering can make the temperature distribution of the sintered material more uniform, reduce the sintering temperature, shorten the sintering time, and obtain barium titanate ceramic products of the same quality or higher quality as other sintering processes.

Barium titanate ceramics can be used to manufacture capacitors, thermal components, piezoelectric devices, dielectric amplifiers, frequency modulators, voltage regulators, etc. it can be used in various fields such as electronics, communication, household appliances, automobile, military industry and so on. MLCC (chip multilayer ceramic capacitor) is an important application market of barium titanate. MLCC is the mainstream product type of ceramic capacitors, with a market share of more than 90% and a high demand level. In 2019, China's MLCC market scale was about 50.6 billion yuan, with a year-on-year increase of 12.3%, and continued to maintain a rapid growth trend. The good development of MLCC industry provides sufficient space for the development of barium titanate industry in China.

Barium titanate ceramics have excellent dielectric properties and can be used to manufacture small volume and high-performance electronic components. With the continuous progress of technology in China's consumer electronics, home appliances, automobiles, communications and other industries, the demand for electronic components is becoming increasingly miniaturized and high-end, and the demand for barium titanate ceramics also shows a high-end trend. In order to support the development of downstream industries, China's barium titanate ceramic industry needs to continuously improve its technology, narrow the gap with international advanced enterprises and realize the import substitution of high-end products.

|

|

|

|